Aws Cwi Things To Know Before You Buy

Aws Cwi Things To Know Before You Buy

Blog Article

Not known Details About Aws Cwi

Table of ContentsEverything about Aws CwiAws Cwi Can Be Fun For AnyoneSome Known Incorrect Statements About Aws Cwi The Best Guide To Aws CwiGet This Report on Aws Cwi

Have you ever before thought about a profession as a welding examiner? A welding evaluation accreditation is not only a fantastic success, it verifies your capabilities in the welding market.

Coming To Be a Certified Welding Inspector shows your commitment to growing within the welding industry. This accreditation is one that should not and will certainly not be forgotten! As a CWI, you'll have the ability to capitalize on a number of various possibilities among sector experts.

Licensed Weld Inspectors are an unbelievably beneficial and beneficial asset for metal makers. Their presence is fairly beneficial for any type of company employing the fabricators that bring them aboard. As you might recognize, welding is just one of the most complicated solutions within the metal fabrication sector. The end result of every welding project is highly reliant upon specific welder skill.

Not known Factual Statements About Aws Cwi

There's no question that CWIs assistance to support higher degrees of consistency and top quality to the welding divisions they supervise. This blog site message gives a brief review of the major advantages of working with a metal manufacture company that uses licensed weld assessors. It's not unexpected that many top-level markets will require you to work with certified welding inspectors to oversee welding.

Certified welding examiners have years of experience and thus, they comprehend the subtleties of compliance with welding codes. Adhering to the welding procedure, CWIs can perform a collection of test to inspect the top quality of a weld, consisting of visual examination, warmth treatment and a hydrostatic examination. AWS CWI. They can also make the appropriate modifications to the pre-weld prep work and the in-weld procedures as necessary

An internal qualified welding examiner will have the ability to assure that your project is customized to all the demands of relevant welding codes, guaranteeing its high quality. Welding assessors can examine welding procedure requirements, building and welding plans, equipment calibration and welding materials. A welding assessors ability to offer welding treatment specs supplies the metal construction company a substantial edge of the competitors, enabling producers to develop welds that ideal fit specific components, rather than making use of reliable welds.

3 Easy Facts About Aws Cwi Described

As formerly discussed, a CWI is not just accountable fore creating the procedures for the weld, yet also the quality-check screening procedures. https://qualtricsxmh3f2cs9tw.qualtrics.com/jfe/form/SV_03sfQMGSkX0iCUK. Beyond that, welding assessors work to make certain that tools is properly prepped for the work and that welders are able to complete their welds with proficiency (Welding Inspection Agency). A certified welding inspector will have had several years of experience, which a steel manufacture business can utilize to make certain excellent results for all construction tasks that entail welding

This is why it's crucial to discover a welding firm with an experienced and highly educated internal qualified welding examiner on team. The good news is, CAMM steels is such an organization, so call us today if you have a future job that calls for high quality custom-made welding! It's clear that a personalized steel construction vendor with internal CWIs has dedicated to purchasing the high quality of its welds.

Here at CAMM Metals, after the welding section of the task is complete, we supply many in-house services. These solutions consist of weld inspection with color penetrant, acid cleansing and polishing of stainless steel welds.

For those customers that require qualified welds, we can certify our welds to AWS D1.1 & AWS D1.6.

The Buzz on Aws Cwi

It's important to note that several employers don't always need you can check here welders to be licensed. The main distinction is that qualified welders have composed records of their test results and their performance is frequently kept track of with regular assessment( s) being component of the efficiency record for each welder.

Prior to taking the examination all PFS welders are trained, if needed, in the actual welding process that they will certainly be making use of and they will certainly require to have a functioning knowledge of the welding devices, welding palatable and the product to be bonded. Successfully passing one test will enable the welder to work with lots of sorts of fabrications however will certainly not allow him to work on all kinds of fabrication as there are qualification ranges enforced for each examination configuration.

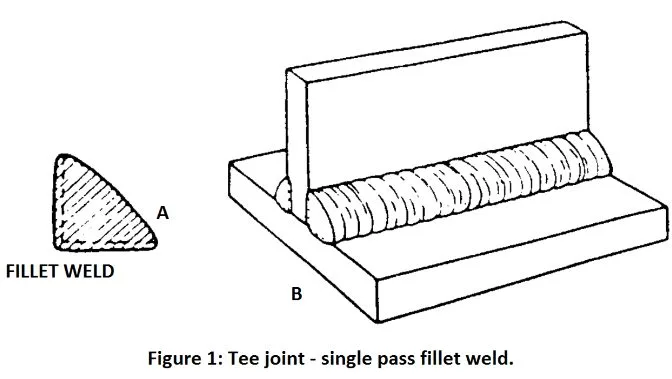

Necessary variables consist of yet are not restricted to product type, consumable type, product density and welding setting. etc. After the welder has finished his examination plate or pipeline the weld is checked utilizing the complying with NDE processes: Aesthetic Examination X-Ray Fluid Penetrant Testing In some cases, the weld is additionally destructively examined.

The Definitive Guide for Aws Cwi

PFS achieves this utilizing a connection report that information all welds that a welder makes. If a welder does not use the welding procedure in a 6-month period, after that they shall be requalified because process. The advantages to using a qualification system are numerous yet the major advantages are: It confirms the skill of an individual to do based on a qualified welding treatment specification (WPS) to generate an excellent weld.

Report this page